KHOSLA MACHINES P.LTD.

Featured Products

Highest quality standards are achieved through the implementations of latest technology, decades of experience and everlasting moral values , which have helped us to retain our customers as well as multiply them.

Welcome to KHOSLA MACHINES P.LTD.

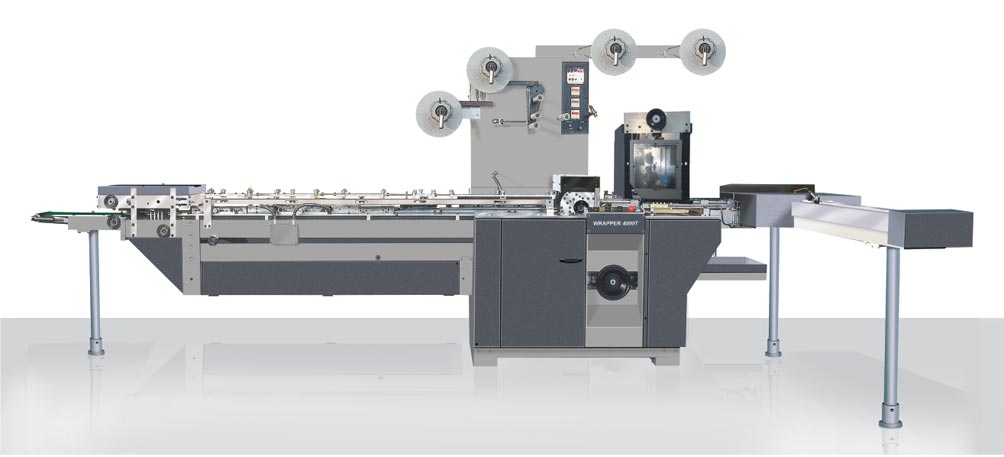

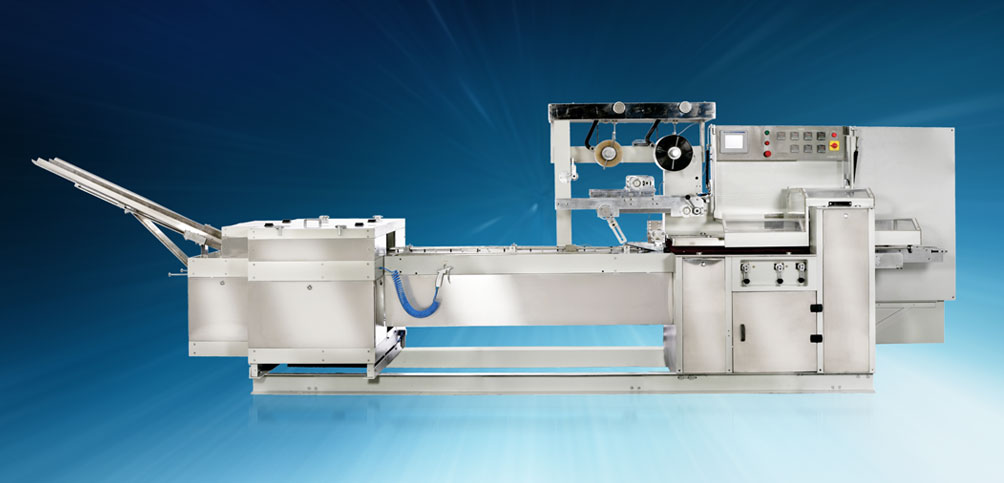

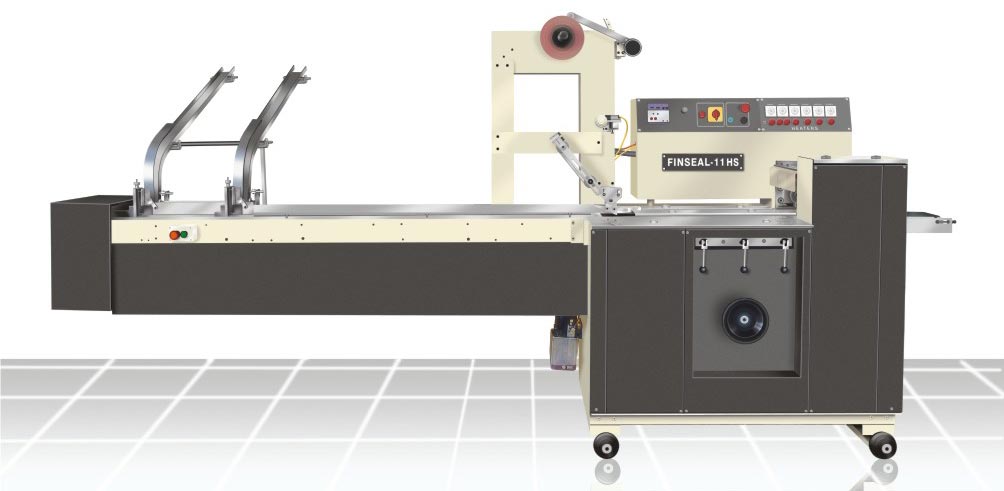

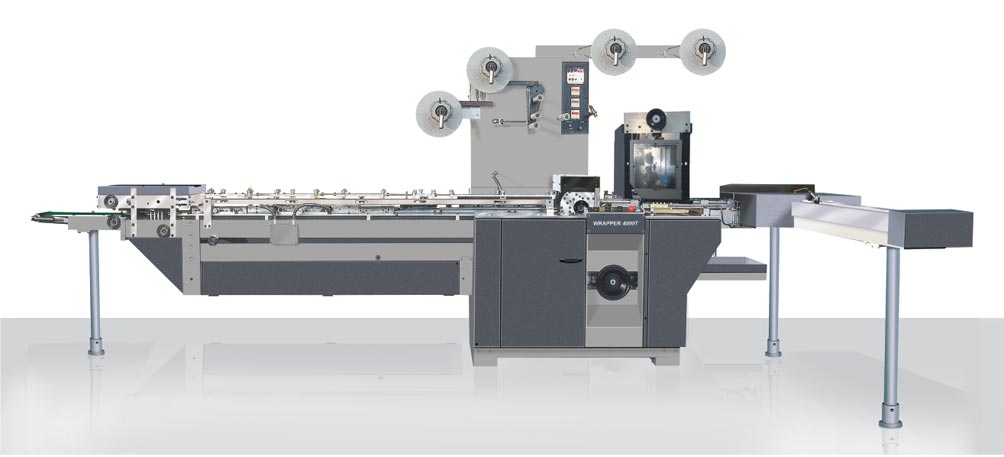

Toilet Soap Wrapping Machine

STANDARD FEATURES

» Outer wrapper and inner stiffener

» High speed operation of upto 160 tablets per minute

» The new design Autofeed Conveyor provides attention free linking with the cutting machine / stamping machine to match the speed of production

» Excellent quality of soap handling, even for soft soap

» Timing Belts allow maintenance free operation for longperiods

» Automatic centralised lubricationl Double spool holder to save reel change over time, integrated with “wrapper-break-machine-stop” interlock

» Simple to maintain “no-soap-no-wrap” interlock

» Long top and side heaters with Cooling Plates for reliable sealing at high speeds

» Digital temperature controllers for all heaters (separate front and rear side heaters)

» Worm drive for accurate print correction

» Easy height adjustment of cutoff unit and discharge conveyor

» Completely guarded drives

» All parts in contact with soap are either stainless steel or coated with Teflon. Conveyor belt is of food grade quality

Highlights

» Low and easy maintenance

» Link ability

» High Productivity

» Easy soap size change

Options: » Inkjet coder

» Flexible infeed conveyor to suit plant layout

» Collator on discharge for easy pickup of soap e Conversion parts for size change

» Conversion parts for size change

MACHINE SPEED UPTO 160 PPM INFINITELY VARIABLE

Our Vision

* To embrace new technologies and methods. * To give unsurpassed products and services to the clients. * To constantly look for improvement and changes.